My name is Yaroslav Kravchenko and I work as a researcher at Sumy State University. Until recently, my scientific interests were limited to work in the field of solid state physics and condensed matter physics. The period of study in graduate school and the subsequent dissertation work were devoted to the study of the structural - phase state and mechanical properties of multilayer nitride coatings. Academic mobility and cooperation with researchers from different countries have become a good incentive to expand the scope of scientific interests. The current project provides for interdisciplinary work at the intersection of physics and biomedicine, and also provides for two directions: the development and synthesis of a new class of nanolaminate bioinert coatings with antibacterial properties and the development of a bioresorbable material for bone implants with the possibility of 3D printing.

Bioinert nanolaminate coatings

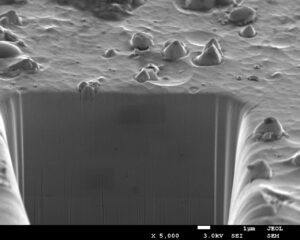

The development of new competitive materials for surface modification of implants that meet the criteria of safety and effectiveness is a modern challenge. According to statistics, the number of patients who need surgery to prevent the development of severe degenerative-dystrophic diseases is growing rapidly. Thus, the restoration of joint function by arthroplasty is more than 17% of all orthopedic surgeries. In Ukraine, the highest percentage of late postoperative complications is recorded in orthopedics and is about 25%, which causes a high need for improvement of orthopedic structures and instruments. The disadvantage of many modified metal implants is the low adhesive strength of the coating to the base and the lack of additional antibacterial protection. Given the above facts, a group of physical vapor deposition (PVD) methods will be used to modify the surface of metal implants, bone osteosynthesis plates and bulk structures. The advantage of PVD methods is the high adhesive strength of condensed materials, which is due to the high energy of the deposited particles. A combination of physical vapor deposition methods and the addition of N2 reaction gas is used to synthesize coatings with high mechanical properties. The degree of ionization and the energy of the deposited particles for PVD methods is quite high, thus achieving high values of adhesion of the condensed material (> 63 N) to the implant.

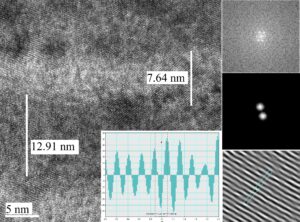

Currently, binary monolayer alloys of titanium and zirconium are widely used, both in the form of nitrides, oxides, and metal compounds for the modification of implants. One of the possible options for improving monolayer coatings is to create a nanolaminate architecture with multiple duplication of bilayers. The nanolaminate architecture makes it possible to influence the structural-phase state of the coating by varying the modulation period (λ) of the layers and combining the advantages of different components. The synthesis of epitaxial condensates with nanolaminate layers, in addition to combining the advantages of different materials, can lead to increased physicochemical properties, such as corrosion resistance and adhesion of the layers to each other by increasing the number of interfaces. It is planned to experimentally implement epitaxial or congruent growth of bilayers in multilayer nanolaminates Ti1-xCuxN, Ti1-xCuxN/ZrN, Me1-xCuxN/ZrN (where Me is a biocompatible metal) with a variable elemental composition. The acquisition of antibacterial properties of bulk structures is assumed after the implantation of Ag + ions in the near-surface layer of condensate or by creating an additional layer on the surface.

The analysis of the biocompatibility of the coatings will be carried out by assessing the metabolic activity of osteogenic cells, in particular, a comprehensive assessment of their proliferation and metabolic profile (synthesis of alkaline phosphatase, collagen, calcium deposition) on the surface of nanolaminates will be performed. The features of the antibacterial action of the implanted silver nanoparticles will also be established. Experiments using cell culture will be conducted according to the recommendations of ISO 10993-3: 2014 and ISO 10993-5: 2015, which will allow the use of research results to form recommendations for the industrial use of the results. At the end of the preliminary test cycle, the nanolaminate coatings will be deposited on the surface of the bone osteosynthesis and/or metal endoprosthesis plates, followed by a study of the tribological characteristics.

Bioresorbable materials with the possibility of 3D printing.

In our time, technologies have appeared and are rapidly developing that can at least partially reproduce some structures and processes occurring in living organisms. Biomimetic materials that reproduce and imitate natural systems have promising potential.

Biomimetic materials, or biomimetics (English biomimetic materials, biomimetics, bioinspired materials from the Greek “bios” - life and “mimeticos” - to imitate), are created on the basis of principles that already exist in nature. These are macro-, micro- and nanoscale synthetic structures, which are analogs of fragments of tissues, organs or biologically active metabolic products that repeat the properties of living systems. This class of materials includes peptides, lipids, and organic polymers, as well as bioinorganic composites for tissue engineering applications.

Polymer nanocomposites based on chitosan and hydroxyapatite can serve as an excellent basis for bone tissue, like an extracellular matrix for bone tissue regeneration. Modern technologies allow the use of 3D printing to create implants in order to restore the affected areas of bone tissue or structures that contribute to its regeneration. The work of the project will be aimed at the development of a series of compositions based on polymers with the addition of hydroxyapatite for printing porous structures that can be implanted into damaged areas with subsequent bioresorption. The possibility of creating an active surface of metal implants based on hydroxyapatite to improve cell profiling processes is being considered.

An additional challenge is the development of a formulation that can be printed on standard extruders for printing PLA plastic by lowering the extruder temperature. Typical printing temperatures close to 200°C will cause degradation of biodegradable polyesters, which should form the viscous base of the material. The settings for printing at lower temperatures (below 100°C) will be edited. The print filament will be created separately. By creating filament in a separate extruder, we can resort to using cheaper 3D printers. This will reduce the cost of manufacturing the final product. At the initial stage, the technology of printing on arbitrary geometric shapes will be tested. As the technology improves, the possibility of combining structures with metal implants is being considered.

Yaroslav is the recipient of a small research grant from the US-Ukraine Foundation Biotech Initiative

Scopus

Google Scholar

ResearchGate

ORCID

2021 IEEE 11th International Conference on "Nanomaterials: Applications & Properties" (NAP-2021)